About Us

About Us

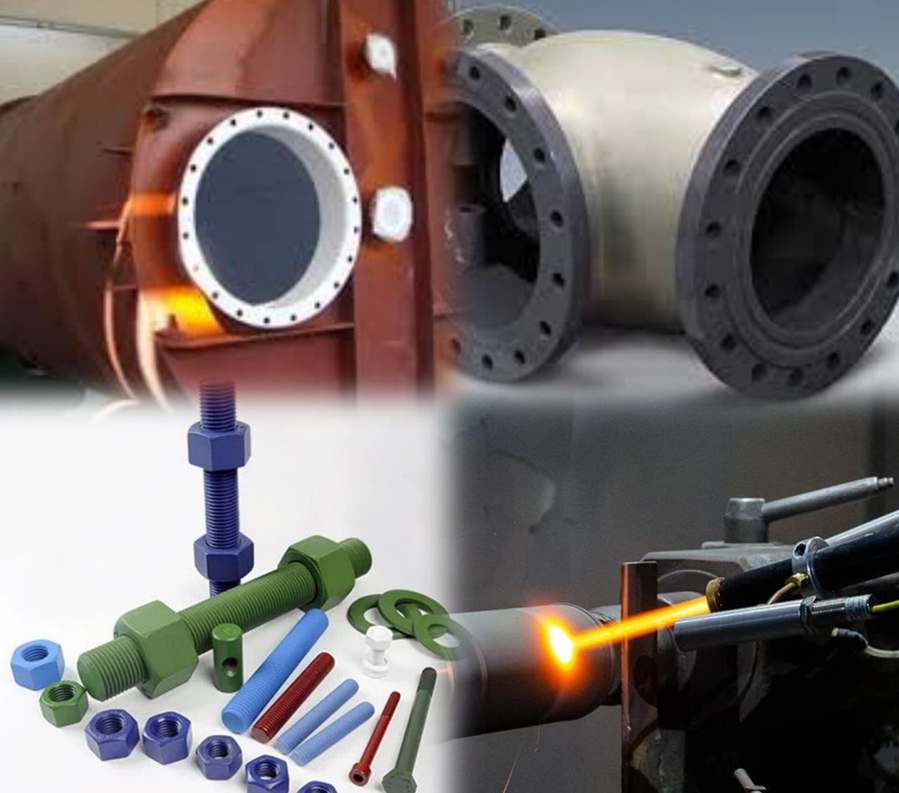

Liquid Epoxy Coating system is designed to help protect steel pipe and other metal surfaces from the harsh effects of corrosion. It provides long-lasting protection in critical industrial applications. We apply Liquid Epoxy coating on both internal and external surfaces of pipes and spools.

Brackish Water, Fire Water & Sea Water Pipelines

Automated Spray & Coating Systems

Internal & External Pipe Coating

Pipeline Coating

Pipeline Coating

We provide a comprehensive range of girth weld coating services to protect pipelines from corrosion and environmental damage. All coatings comply with industry standards such as SAMSS, AWWA, KOC, QATAR ENERGY, and CAIRN.

We apply high-performance shrink sleeves and protective tapes that ensure effective sealing and corrosion resistance at girth welds.

This cost-effective coating method offers solid protection for buried pipelines and is suitable for various environments.

FBE is a thermoset polymer coating applied through electrostatic spray to protect against corrosion in both onshore and offshore pipelines.

Polyurethane coatings provide excellent abrasion resistance and flexibility, making them suitable for mechanical and thermal protection.

Epoxy-based coatings deliver high chemical resistance and strong adhesion to pipe surfaces, ensuring long-term durability.

Our coatings meet stringent global specifications such as SAMSS (Saudi Aramco), AWWA (American Water Works Association), KOC (Kuwait Oil Company), QATAR ENERGY, and CAIRN standards.

Liquid Epoxy & Girth Weld Coating

Liquid Epoxy & Girth Weld Coating

Liquid Epoxy Coating is a durable anti-corrosion solution applied to metal surfaces. It provides a tough barrier against environmental stress, enhancing the longevity of steel pipes and spools.

Used across Brackish Water Pipelines, Fire Water Pipelines, Sea (Brine) Water Pipelines, and Vessels Internals to prevent corrosion and ensure long service life.

We use an Automated Hollow Cone Spray System for smaller diameter pipes and Automated Internal Coating Equipment for larger diameter spools and pipelines.