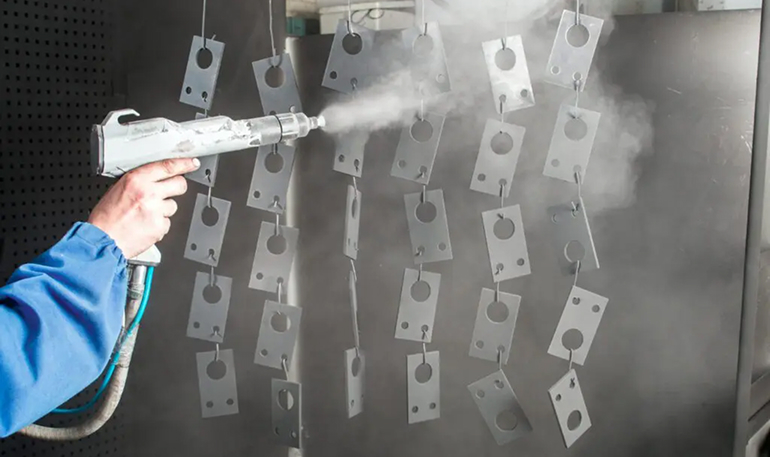

PTFE (Polytetrafluoroethylene) coatings, often recognized under the brand name Teflon, are high-performance fluoropolymer coatings known for their outstanding non-stick and low-friction properties. Applied in liquid form through a precise spray technique, PTFE coatings adhere to a wide range of substrates including metals, rubbers, and plastics. Once cured, the coating forms a durable and protective layer that resists heat, chemicals, corrosion, and wear. This makes PTFE coatings highly suitable for applications across various industries such as automotive, food processing, electronics, and chemical manufacturing. The coating not only enhances component longevity but also reduces maintenance and energy costs by minimizing surface friction.

PTFE coating service ensures a surface that is resistant to chemicals, extreme temperatures, and wear—providing a long-lasting solution that enhances the performance of your equipment and structures.

Our Specialized Coatings

Our Specialized Coatings

A superior fluoropolymer blend designed for extreme conditions. Xylan coatings provide dry lubrication, exceptional corrosion resistance, and long-lasting durability for threaded fasteners, valves, pumps, and automotive parts. Ideal for high-load applications in both oil & gas and chemical industries.

Known for its non-stick properties, Teflon coating offers excellent chemical resistance, low friction, and high thermal stability. Commonly used in cookware, pharmaceuticals, and precision manufacturing industries where hygiene and easy maintenance are critical. It also provides long-lasting protection .

Nylon, also known as Rilson coating, offers superior toughness and impact resistance. It's widely used for coating gears, conveyor rollers, electrical components, and mechanical tools. The coating acts as an insulator, providing resistance to wear, chemicals, and harsh environments.

PTFE Coating Experts

PTFE Coating Experts